Key issues in Additive Manufacturing Software

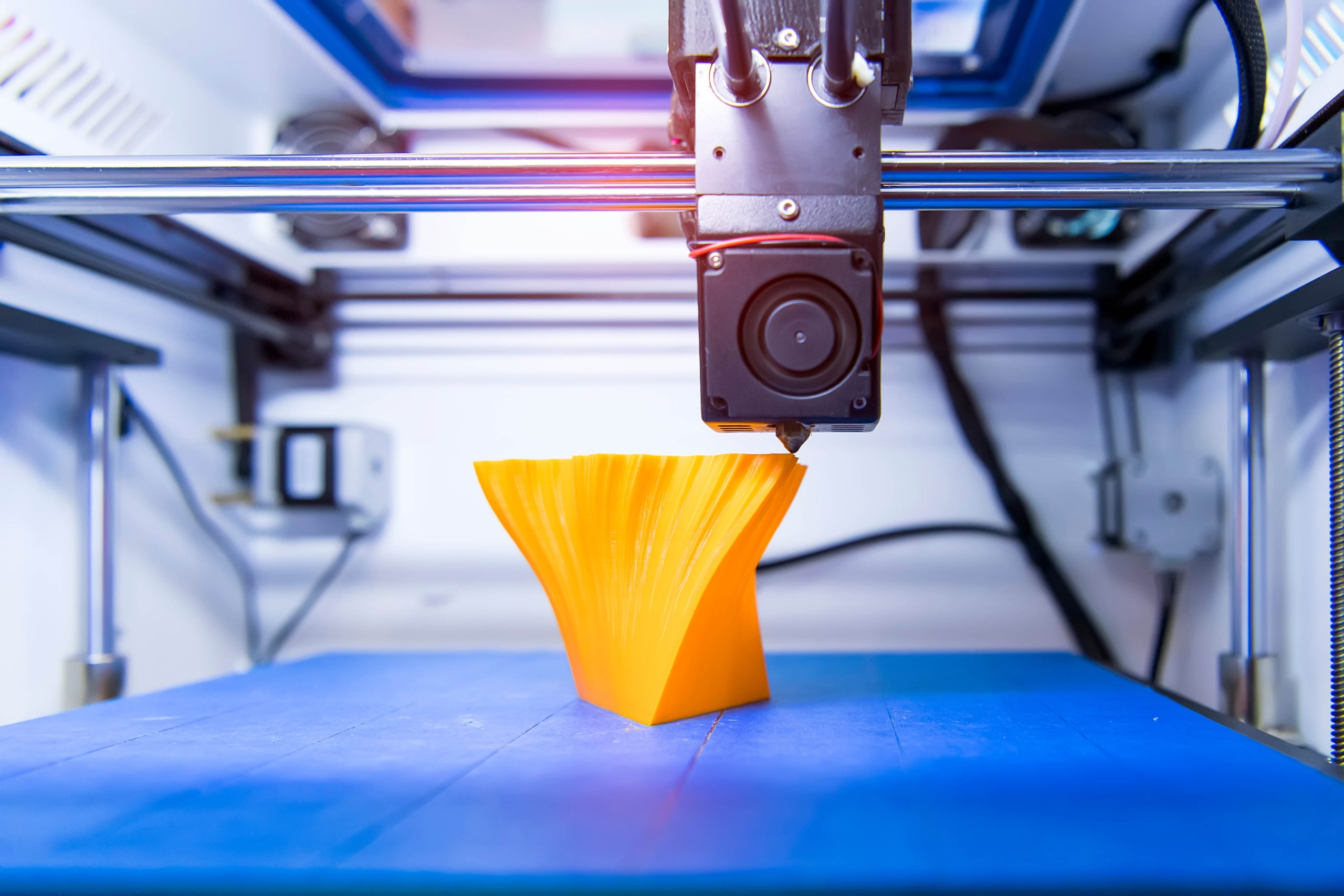

In an ever-changing additive manufacturing environment, engineers and production managers face increasingly complex challenges. The coordination of various players within a single project is essential, as is the rigorous management of consumables. Maintaining a level of quality superior to that of traditional manufacturing is becoming an unavoidable requirement. Data traceability is crucial to guarantee process conformity and integrity, while optimizing project financial management.

The stakes involved in the quality of finished parts are also heightened by increasingly stringent standards. Engineers and designers have to navigate in an environment where every detail counts, from material selection to product validation. In this context, the right solution is a strategic asset. By integrating high-performance tools to manage traceability, quality and materials management, companies can secure their additive manufacturing projects and improve efficiency. This is essential if they are to meet today’s challenges and prepare for the future of production.